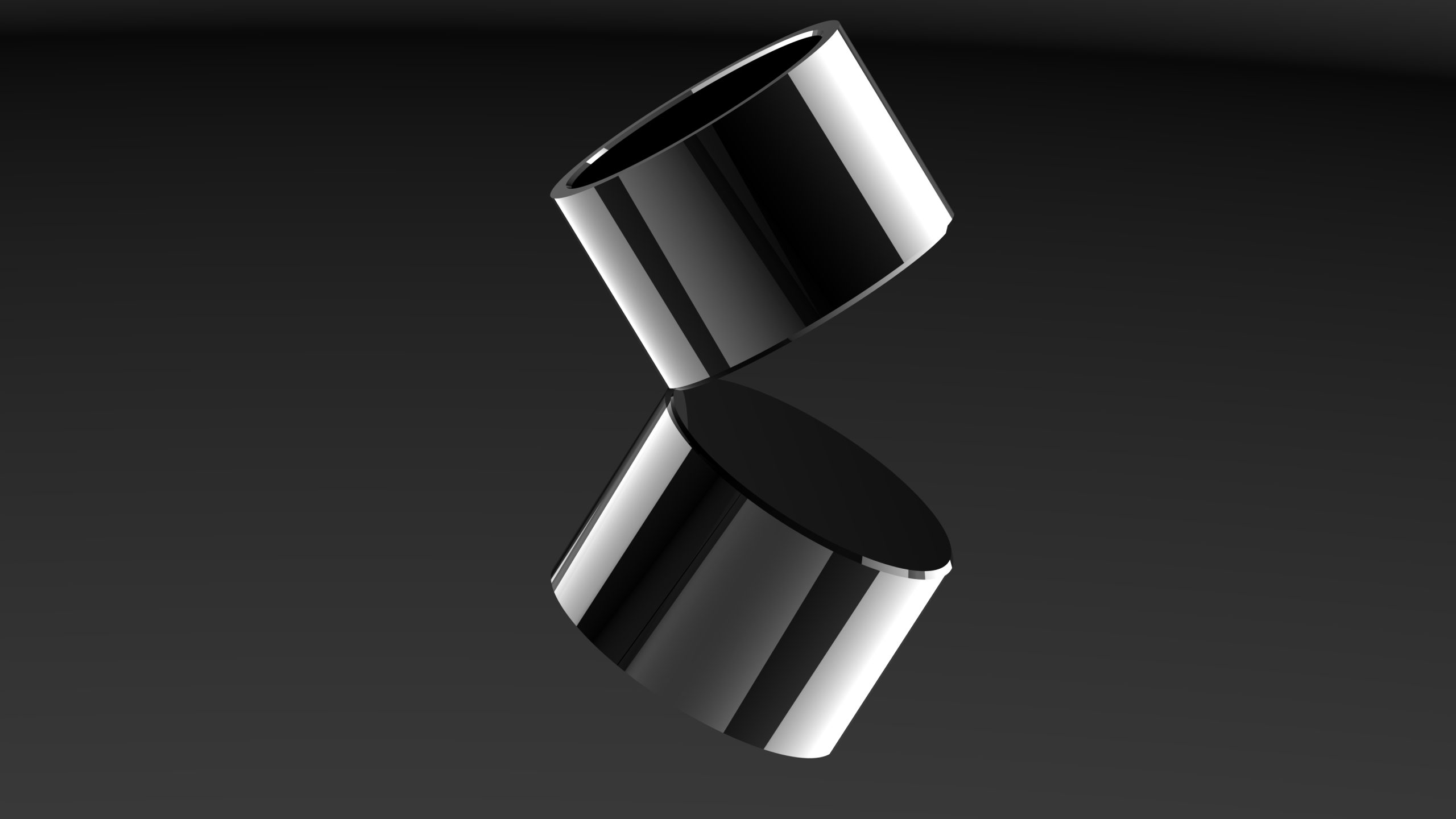

JCVAP Diamondium Insert Grade D for Peak Pro and Pockety

£233.36 £210.02

No-Questions-Asked 3-Day Refund

Get a full refund within three days of receiving your goods—no questions asked, if you’re not satisfied,If the time limit is exceeded, please contact our customer service or email us at se*****@***ap.com with a reasonable explanation.

30-Day Normal Use, Free Replacement

If your goods are damaged within 30 days of normal use, contact our customer service for a prompt replacement.

7-Day Customer Service

Customer service is available seven days a week, except on major holidays..

Diamondium is trade name for a sophisticated nanocrystal. It has the chemical formula SiC and is a rare mineral, Silicon carbide is useful for commercial and industrial applications due to its hardness, optical properties and thermal conductivity.

This new substance will bring a completely new experience and unparalleled flavor to your dabbing.

Diamondium pearls(Grade D) are actually made of Moissanite .It is Single Crystal Silicon Carbide.

In nature, there are primarily three types of SiC, that is 3C-SiC, 4H-SiC and 6H-SiC

The crystal structure of Moissanite consists of a hexagonal lattice formed by silicon and carbon atoms(6H-SiC), with each unit cell containing six silicon atoms and six carbon atoms. This structure gives Moissanite its hardness and fire similar to that of diamonds.

These three structures have different thermal conductivities.

That means the thermal conductivity of Moissanite is more than twice that of ALN(Aluminum nitride).

What’s the difference between ordinary SiC insert and Diamondium insert?

1.The molecular structure is different. Traditional silicon carbide is 3C-SiC, while Diamondium insert is 6H-SiC.

2.Diamondium insert composed of nearly 99% silicon carbide, original SiC insert composed of about 90% silicon carbide and 10% other components, such as iron, nickel and carbon, etc.

3.Diamondium insert has a better thermal conductivity.

How to distinguish between Diamondium (Grade D) SiC and regular SiC?

You will know by shining a light on them with your mobile phone.

All the above data and information come from the following references:

1. M.S. Aziz, Z. Mohammed, R.I. Alip. 2018. Faculty of Electrical Engineering. The Effect of SiC Polytypes on the HeatDistribution Efficiency of a Phase Change Memory.

2.Harris, G.L. 1995 Thermal conductivity of SiC, 5-6.

3. Goldberg Yu., Levinshtein M.E., Rumyantsev S.L.2001 Properties of Advanced Semiconductor Materials GaN, AlN, SiC, BN, SiC, SiGe, 93-148.

4. Amirthan G, Udaya A, Balasubramanian M. 2011 Thermal conductivity studies on Si / SiCceramic composites. 09 003.

Monocrystal SiC is an exotic hard material that has only recently become commercially available. It is exceedingly difficult to produce and requires substantial amounts of energy and infrastructure.

This material is powering the future of high energy density electronics, especially pertaining to charging stations for electronic cars where extremely high levels of power dissipation are required. Beyond this, Monocrystal SiC has the potential to be utilized in a multitude of end use applications from defense industries,chips and semiconductors to medical implants and more.

Monocrystal SiC is produced through a highly refined process of essentially vaporizing high purity silicon carbide or SiC precursors and condensing the vapor atom by atom into an extremely high purity, monocrystal boule. This process gives the silicon carbide a perfect or near perfect monocrystal lattice structure, which massively increases its thermal conductivity by comparison to ceramic silicon carbides, or virtually any other hard material on the planet (other than diamond). This process also creates a 99.9999% pure material that is extremely homogenous and has little to no inconsistency whatsoever.

Thermal conductivity of 490 w/m/k yields an unprecedentedly low operating temperature as little as 330*F, which is far lower than any other vaporization surface currently available on the market.

Low specific heat capacity coupled with high conductivity yields fastest heating of any vaporization surface (Thermal Diffusivity)

The exceedingly low emissivity coefficient that results from mirror polishing yields an extremely slow rate of cooling. On a thermal camera, this product will appear to be similar to background / room temperature even when above 500* Fahrenheit.

Torches clean in only seconds thanks to it’s ultra thermal diffusivity.

Nontoxic & Biocompatible.

Melting point of over 5,000*F.

If you have any questions, or need additional photos, feel free to DM us on IG @jcvaptech or email us at se*****@***ap.com.

| Weight | 50 g |

|---|

You must be logged in to post a review.

Related products

-

Ruby Insert for ICA/RBA ,3D&5D Chamber

£76.50£68.85 -

Glass Water Filter for Pro

£22.95

£20.66 -

Whip Silicone Adaptor Cap

£3.82£3.44 -

JCVAP Coil for Puffco Peak Atomizer(5pcs/Pacak)

£10.70

£9.63

-

JCVAP Pockety Electric Dab Rig – Portable Vaporizer with Dual 2600mAh Batteries-UK Edition

Rated 5.00 out of 5£114.39 – £209.22Price range: £114.39 through £209.22

£102.95 – £188.30Price range: £102.95 through £188.30

-

Grinder Herb Electric VYRO

£25.00£22.50

-

Pipe Glass Blunt Twisty 2.0

£3.09

£2.78

Reviews

There are no reviews yet.